What is a Biotrickling filter system?

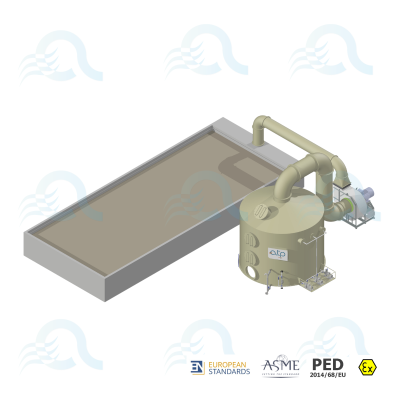

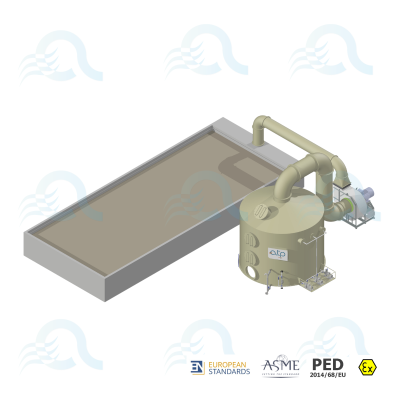

A biotrickling filter system is an advanced biological technology used for the removal of volatile organic compounds (VOCs) and malodorous gases from industrial emissions. It combines the features of a biofilter and a scrubber. This system harnesses the metabolic capabilities of specialized microorganisms to biodegrade organic pollutants. It involves a packed bed, typically made of inert structured plastic, which supports the growth of a biofilm of these microorganisms.

How does it work?

The operation of a biotrickling filter system involves several steps:

- The contaminated gas stream is passed through the packed bed where microorganisms are immobilized. These microorganisms use the VOCs as a source of carbon and energy.

- Pollutants are transferred to the biofilm and the trickling water, which moves in countercurrent to the gas stream. This water not only feeds the microorganisms but also helps in the transfer of pollutants from the gas to the biofilm.

- The biotrickling filtration system is maintained under specific conditions, like optimal pH levels and concentrations of nutrients and salts, which are periodically checked to ensure efficient microbial activity.

- The biodegradation process results in the production of byproducts, which are purged along with small amounts of washing liquid and biomass.

Finally, the clean gas exits the filtering chamber and passes through a mist eliminator, which removes any remaining liquid droplets.

Which problem can sort it out?

Biotrickling filter systems are highly efficient in removing volatile organic compounds (VOCs) and foul-smelling gases from industrial emissions. It makes them ideal for industries emitting these pollutants. These systems are environmentally sustainable as they use naturally occurring microorganisms to degrade pollutants.

Furthermore, biotrickling filters offer effective and eco-friendly solution for maintaining air quality, ensuring compliance with environmental regulations while promoting a healthier workplace. Their advanced technology and sustainable approach make them a preferred choice for modern industrial air treatment.

![ISO 9001 [Italy] ISO 9001 [Italy]](https://atpenvironment.com/wp-content/uploads/elementor/thumbs/ISO-9001-Italy-1-e1734709424454-qysjxm32zf8e8mhshe2a1tecm8cbvnzg0wb4e904dc.jpg)