case history atp environment

industrial air treatment plants

History is made one ppm at a time

Industrial air tretment plants can be very different from each other according to the process, pollutants and application they serve.

In this page you can see some of our work in many different industries and areas, with technical details, pictures and dygrams.

ATP’s team had to design and build an odor and COV ´ s abatement system for a process air Flow rate of 300.000 m3/h.

For this application the solution chosen was to create 3 parallel lines to be installed at the same time.

Each line includes:

- 1 scrubber,

- 3 biofilter,

- fan,

- electrical panel.

The request was to remove odours from 130.000 m3/h air flow from solid waste mechanical sorting and 10.000 m3/h from storage bunker.

The challenge was to carry the project out in a really reduced area.

The proposed solutions from our team were bioscrubbing after a baghouse filter for mechanical sorting and a carbon filter for the bunker.

The twin bioscrubber towers are in their own right an interesting case study.

The need was to remove odours and ammonia from an air Flow of 130.000 m 3 /h provonient

from an aerobic waste composting unit.

ATP’s team designed for this application a plant composed of 2 parallel lines, each one made of a chemical scrubber and a biofilter.

A case history of its own: the process of ceramic firing generated a process air flow with stiky substances in it along with other pollutants.

ATP’ s team had to develop a first time in history system, which became finally made of:

- 1 scrubber tower,

- 1 demister,

- 3 venturi scrubbers

- 2 carbon filters.

In operation the system has prooven great results.

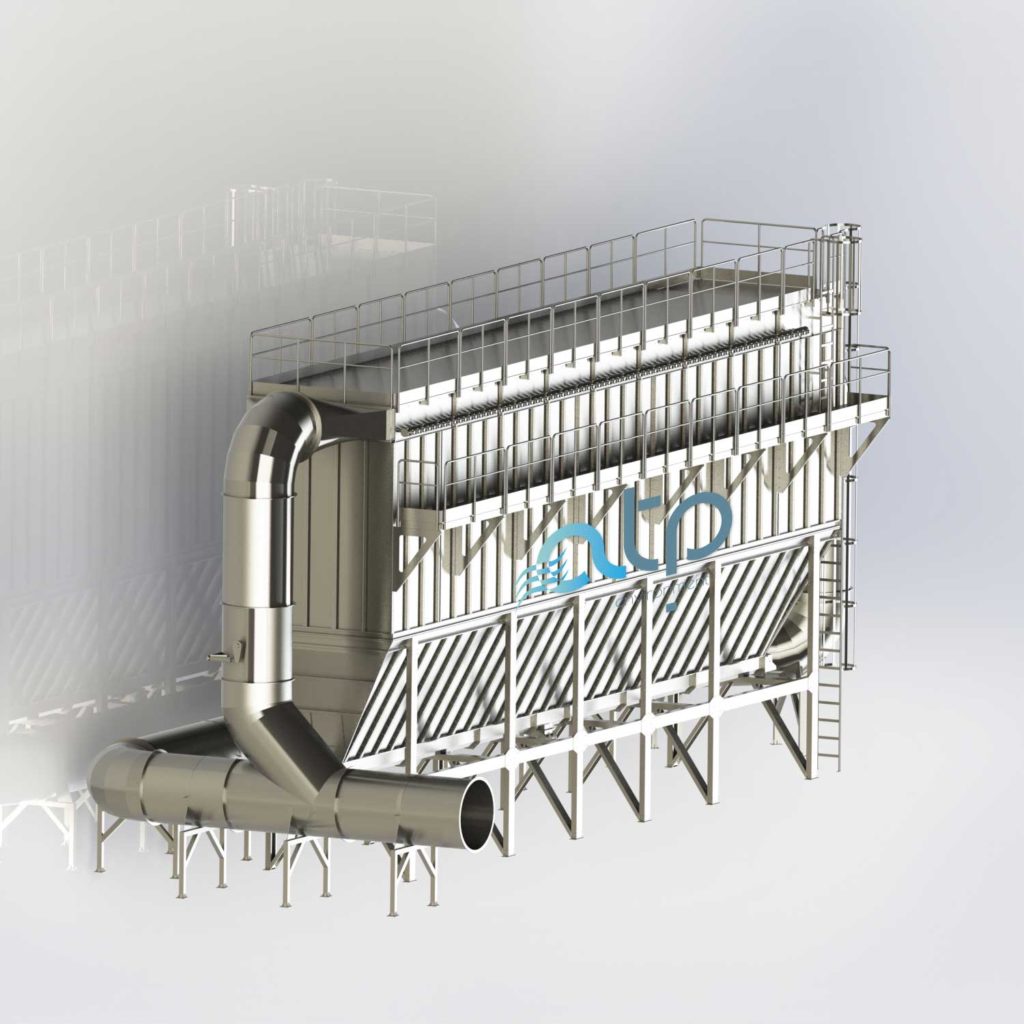

Biomass combustion generates volatile compounds, mainly dusts.

ATP’s team hgas a large experience treating this kind of emissions using, among all the possible technologies, baghouse filters.

In this page we have collected similar application in different world areas and different technical specifications.

biological VOC and ODRS TREATMENT FOR FOUNDRY

The system is engineered to work in two stages:

- the first one is made of 4 sets of Venturi scrubbers

- the second consists in double stage scrubber.

The scrubber works in two stages:

- the first one chemical

- the second Biological according to our patented technology Bioscrubber.

This plans has prooven itself to be very effective for odor and COV treatment, indoor application.

ATP environment srl

VAT IT04724560265

Address: via Camisana 244, 36040 Torri di Quartesolo-Vicenza VI, Italy

Tel. +39 0444380221 | Mail: info@atpenvironment.com

Certifications: