What is a post Oxidation scrubber system?

The Post Oxidation Scrubber is engineered to cool and process the gas emitted from the Power Generation Package (M-252) utilizing a treatment column filled with water and a caustic solution. This system features a quencher and a column equipped with structured internal packing for effective gas treatment. Downstream of the package, a combustion gas pressure regulation blower will regulate the pressure in the system before discharging to a free-standing stack.

How does it work?

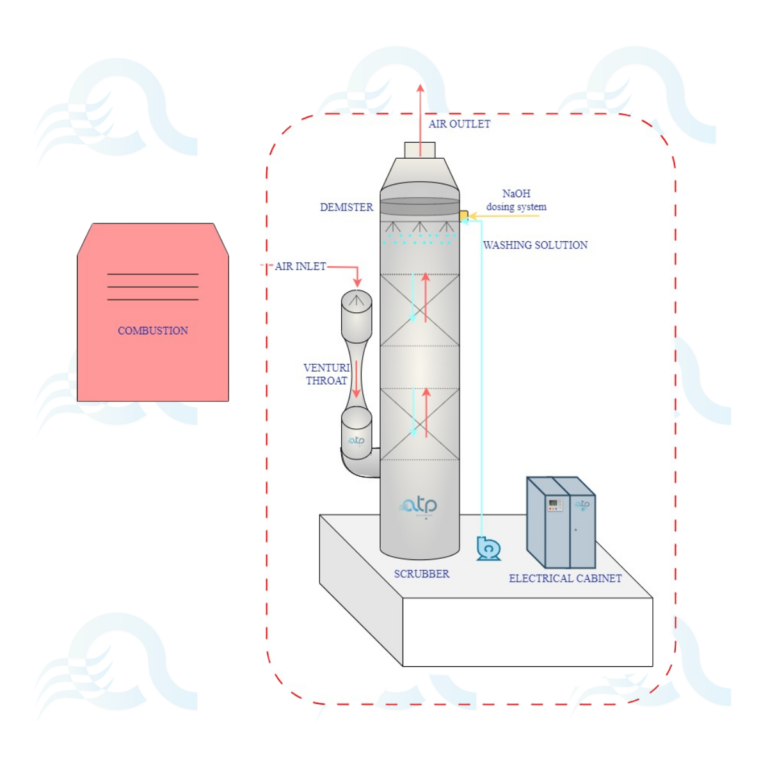

Gases coming from oxidation processes need to be treated before being released to the atmosphere. This is performed through absorption in a venturi scrubber, which is characterized by a converging section, the throat, and a diverging section which is connected to the scrubbing tower. When passing through the venturi throat, the polluted gas stream is washed in co-current with the scrubbing liquid, which is either introduced at the converging section or in the throat. Due to the narrowing of the duct, turbulence increases, and the scrubbing liquid is atomized (reduced into small droplet) allowing for an increased interaction between the droplets and the pollutants.

Leaving the diverging section of the duct, the stream’s velocity significantly reduces resulting in an increased residence time in the scrubbing tower; here, the clean gas is separated with a demister from the liquid entrapping the polluting particles, and it can then proceed to the next step of the process or can be released directly into the atmosphere.

Which problem can sort it out?

The Post Oxidation Scrubber is specifically designed to address the problem of removing pollutants from gases generated during oxidation processes before they are released into the atmosphere. The scrubber efficiently removes SOx, CO, NOx, ensuring that the gas exiting the system is clean and meets environmental standards. This makes it an essential solution for industries looking to minimize their ecological impact and comply with air quality regulations.

![ISO 9001 [Italy] ISO 9001 [Italy]](https://atpenvironment.com/wp-content/uploads/elementor/thumbs/ISO-9001-Italy-1-e1734709424454-qysjxm32zf8e8mhshe2a1tecm8cbvnzg0wb4e904dc.jpg)