What is a Oxy scrubber system?

The OXY scrubbing system is based on the absorption of ethylene/propylene oxides and their subsequent hydration to ethylene/propylene glycols.

The rate of reaction is a function of temperature in the presence of a catalyst, typically sulfuric acid. Energy consumption is minimal. The final product of a system is a glycol solution containing a small amount of acid (3-5%).

How does it work?

The operation of an OXY scrubber generally involves the following steps:

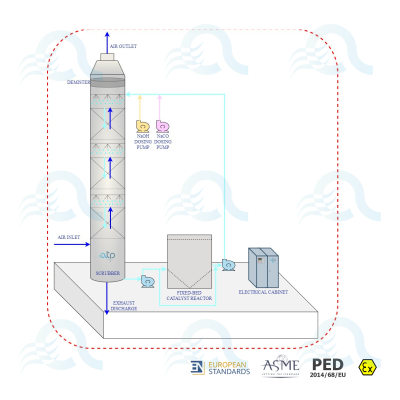

The equipment used for this process is a counter-current packed column where the initial absorption takes place.

The polluted gas enters at the bottom of the column, and flows upward through the packing material, while the scrubbing liquid flows downward by gravity. In the process, intimate mixing and absorption of the gas takes place.

The liquid carries the absorbed gas into the reaction vessel which is designed to allow sufficient residence time for the complete conversion of EO/PO to ethylene and propylene glycol.

What problems can the OXY scrubber solve?

The OXY scrubbing system is specifically designed to address the problem of removing and converting ethylene oxide (EO) and propylene oxide (PO) from polluted gas streams. It effectively absorbs these oxides from the gases and hydrates them into less harmful substances, specifically ethylene glycol and propylene glycol.

![ISO 9001 [Italy] ISO 9001 [Italy]](https://atpenvironment.com/wp-content/uploads/elementor/thumbs/ISO-9001-Italy-1-e1734709424454-qysjxm32zf8e8mhshe2a1tecm8cbvnzg0wb4e904dc.jpg)