TECHNOLOGIES

We are committed to delivering air cleaning technologies tailored for the most demanding industrial applications. We design each system to target specific pollutants, ensuring that the industrial atmospheres our clients operate in a compliant with environmental standards and benchmarks for clean air in their industry and country. Our technologies stand strong against the today’s pollutants and innovations for a sustainable tomorrow.

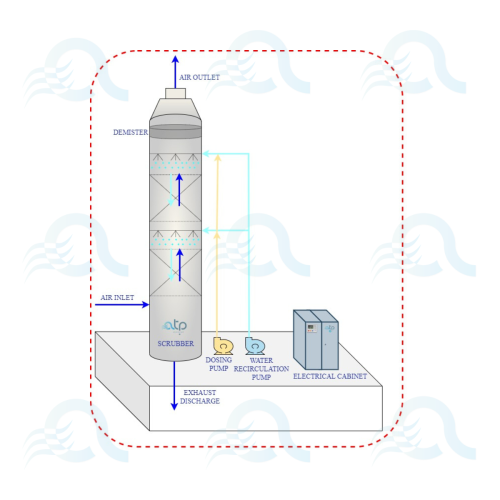

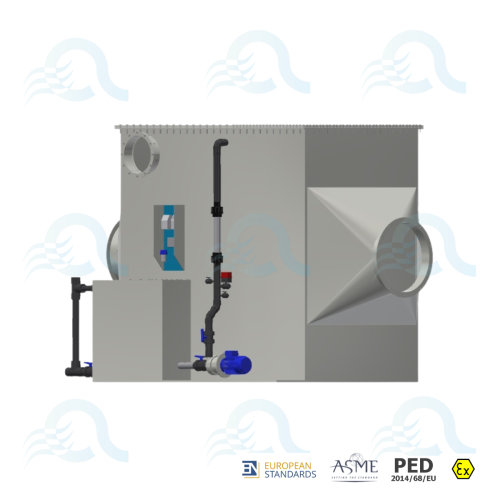

AIR SCRUBBER VERTICAL

The industrial air scrubber is engineered for effective removal of contaminants: air, fumes, gas and vapors, within manufacturing and processing facilities. This technology suits for use in a variety of industrial applications.

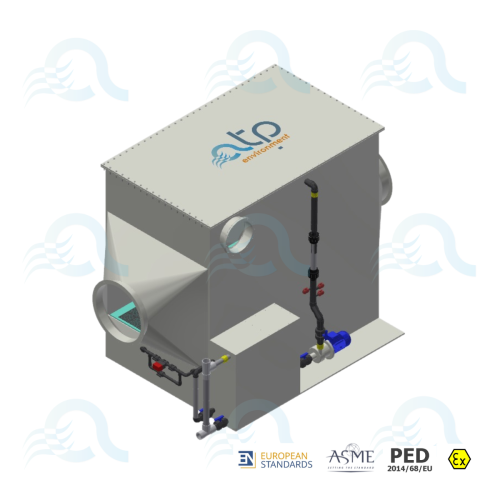

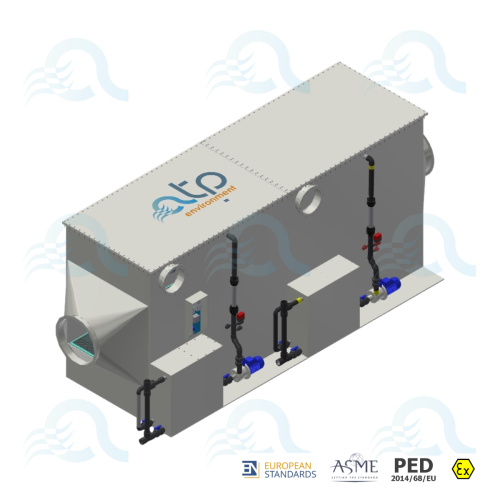

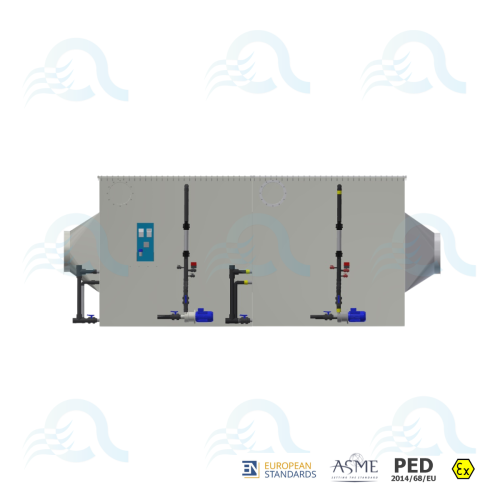

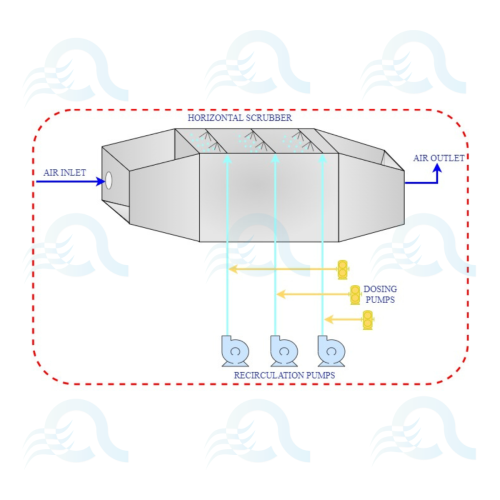

AIR SCRUBBER HORIZONTAL

Our horizontal scrubbers deliver superior emission control by enhancing gas-liquid contact through their horizontal design. This design promotes prolonged interaction, optimizing scrubbing efficacy. Additionally, their horizontal design makes them a space-saving technology.

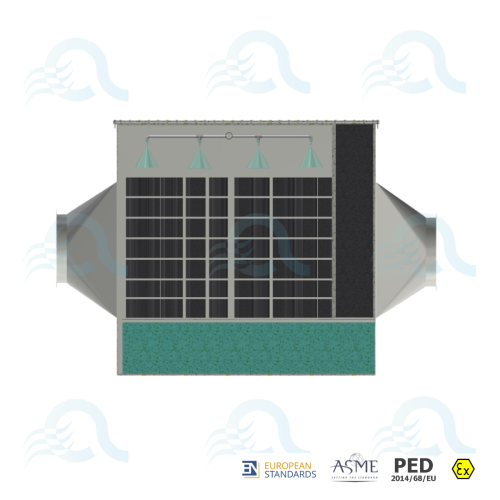

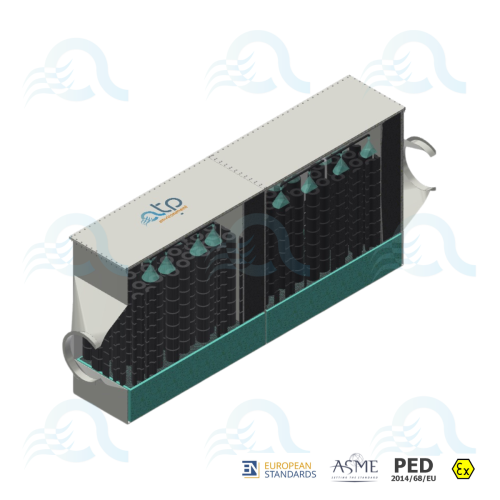

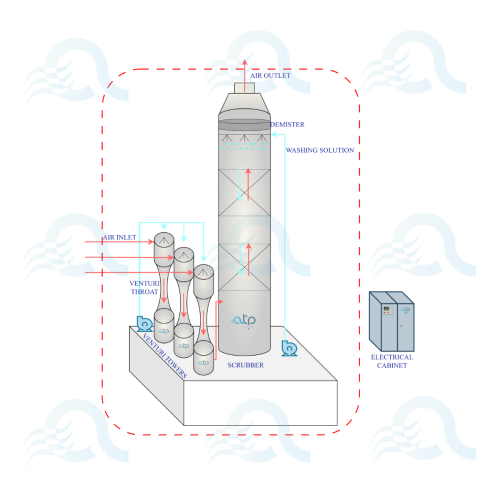

VENTURI SCRUBBER

Harnessing fluid dynamics, these air scrubbers accelerate gas streams, creating turbulence for superior atomization and pollutant capture. Ideal for diverse applications, these systems are key for air purification and scrubber performance.

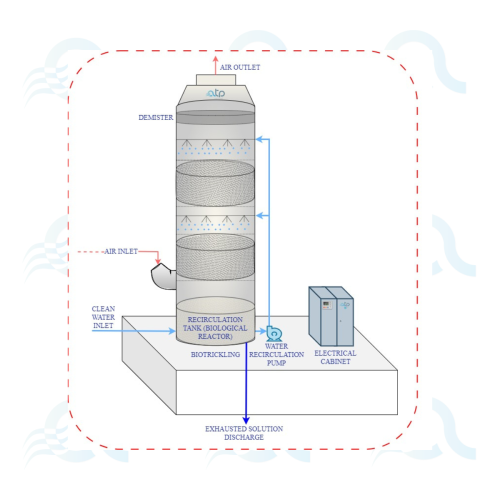

BIOTRICKLING FILTERS

These systems use the natural degradation capabilities of microorganisms to break down and digest pollutants. Ideal for the removal of odorous compounds and volatile organic chemicals, biotrickling filters offer an eco-friendly alternative that aligns with the principles of green technology.

frequently asked questions

Some answers to frequently asked questions about our industry

To identify the most suitable technology to reduce industrial emissions, whether fumes, gases or polluted/odorous air from production processes, it is essential to analyse various factors:

- characteristics of the fluid: composition, temperature, volume (flow rate in m³/h) and humidity

- available space: evaluate the area required to install the abatement system

- investment budget: consider the costs of purchase, installation and maintenance.

After collecting this data, it is possible to identify the most suitable technology to reduce emissions. In more complex cases, it is advisable to rely on a specialised company for a preliminary study, known as FEED Engineering. This process allows you to evaluate the different technological options, analysing the operating costs (OPEX) and investment costs (CAPEX), thus ensuring the choice of the most efficient solution.

The technology for the abatement of dust and other kinds of PM (particulate matter) from air currents must be chosen based on the size, weight and composition of the dust and the air flow that contains it. In fact, depending on the industrial process of origin, the air can contain different types of dust, such as

- metallic dust

- plastic particles

- dust from the food industry (starch, shells, flours)

- dust from waste treatment

- dust from the recycling of batteries and electronic components

and many others. In many cases the best solution is wet technologies such as the venturi scrubber, or dry technologies such as bag filters or absolute filters. If you have a problem with PM emissions contact ATP environment team to know which technology best suits your application.

Industrial emissions restrictions vary by industry and country. It is recommended to contact local environmental agencies to learn about current regulations. If the production process does not comply with industrial emissions regulations, it is necessary to install an air/gas purification system that specifically designed by a company with experience in the sector such as ATP environment. Given the concentration of incoming pollutants and the limitation on emissions, our team of experts will prepare a suitable engineering solution.

The limitations on industrial emissions into the atmosphere vary according to the industry and the country where the companies operate and for this reason we recommend contacting local environmental authorities to find out the current regulations. In the event that the production process does not comply with the regulations on industrial emissions, it is necessary to install an air/gas purification system, specifically designed by a company with experience in the sector, for example, for gaseous effluents contaminated with acidic compounds, an efficient treatment method can be the use of ATP environment scrubber towers.

Industrial emissions regulations are constantly evolving. If your country has lowered emission limits and you already have an air treatment system, it is essential to comply to avoid fines and plant shutdowns. If, however, you did not have a system, it may make installation necessary. In any case, rely on an expert in environmental technologies for the treatment of industrial emissions. ATP Environment can:

- evaluate the technologies currently in use

- conduct an engineering study for the improvement or replacement of systems

- revamp existing systems

- design, build and install new systems

- ensure compliance with new regulations without compromising productivity

In the world of industrial air scrubber technologies there are three main configurations:

- Vertical “packed bed” scrubbers

- Jet scrubbers (with empty section)

- Horizontal scrubbers

- Venturi scrubbers

The term scrubber generally refers to technologies for the purification of industrial emissions, which use water (clean, or with chemical or biological reagents) to literally wash (scrub) the air.

The dimensions of scrubbers for the treatment of industrial fumes depend mainly on the air flow rate to be treated. However, other factors also influence their dimensions, such as the required abatement efficiency and the composition of the gases. The type of scrubber chosen significantly affects the footprint:

- Vertical scrubbers take up less floor space, but require more space in height

- Horizontal scrubbers, on the other hand, require a greater horizontal area, but reduce the footprint in height and allow for greater weight distribution

Efficiency can be calculated as the percentage reduction of pollutants at the exit of the treatment on the initial input value. The treatment of industrial fumes with a scrubber technology can reach high levels of efficiency, depending on the composition of the incoming gases and the correct engineering of the air treatment plant. In some cases, scrubbers can reach 99% efficiency on the reduction. To have a high reduction efficiency in the most severe cases of contamination it is necessary to contact experts such as the team of engineers at ATP environment.

In the case of water-soluble VOCs, the recommended technologies for odor treatment are air scrubbers, bioscrubbers and biofilters. In general, removing unpleasant or nauseating odors from the air coming from industrial processes is not a trivial matter as the substances that generate them can be of various natures. For this reason is important to conduct a gas analysis and consult with an air treatment expert such as ATP environment that can identify the best technology for your odor problem.

The term scrubber usually refers to technologies for the purification of wet industrial emissions, that is, those that use water (clean, or additive with chemical or biological reagents) to literally have (scrub) the air. It is therefore an excellent solution in the case of water-soluble polluting compounds, or with good wettability, that can react with acid or oxidizing solutions based on their nature.

any question?

GET IN TOUCH WITH US

Looking for an answer quickly?

Ready to start your project?

Send us your application details filling a more detailed form. We’ll have all the information we need to answer at the best:

© ATP Environment s.r.l. All rights reserved.

ATP environment srl

VAT IT04724560265

Address: via Camisana 244, 36040 Torri di Quartesolo-Vicenza VI, Italy

Tel. +39 0444380221 | Mail: info@atpenvironment.com

![ISO 9001 [Italy] ISO 9001 [Italy]](https://atpenvironment.com/wp-content/uploads/elementor/thumbs/ISO-9001-Italy-1-e1734709424454-qysjxm32zf8e8mhshe2a1tecm8cbvnzg0wb4e904dc.jpg)