What Is A Venturi Scrubber?

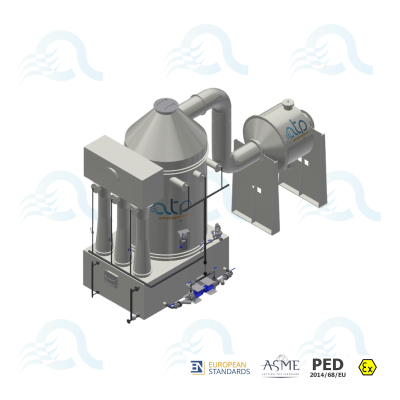

A Venturi scrubber is a type of air treatment plant that uses a liquid (often water) to capture and remove pollutants from a gas stream. This device is characterized by a specific structure comprising three main sections before scrubbing step: a converging section, where the gas stream is initially introduced; a throat, which is the narrowest part of the scrubber, where the velocity of the gas stream increases and scrubbing liquid is introduced and a diverging section, where the gas stream slows down, allowing for more effective interaction between the liquid and the pollutants.

How does it work?

The working principle of a venturi scrubber involves several steps:

- The polluted gas stream first enters the converging section, where it starts to accelerate. As the gas stream passes through the throat, it reaches its maximum velocity. Here, the scrubbing liquid is introduced, either at the converging section or directly into the throat.

- The high velocity and turbulence in the throat cause the scrubbing liquid to atomise into small droplets, which increases the surface area for interaction between the droplets and the pollutants in the gas stream.

- In the diverging section, the velocity of the gas stream decreases, allowing for a longer residence time. This enhances the scrubbing process as the droplets capture more pollutants.

Finally, the cleaned gas is separated from the liquid in the scrubbing tower. A demister removes the liquid droplets entrapping the pollutants, allowing the clean gas to either proceed to the next process step or be released into the atmosphere.

Which problem can sort it out?

They are particularly good at removing fine particulates and soluble gases from industrial exhaust streams.

They can handle high-temperature and high-humidity gas streams, making them suitable for various industrial applications.

Venturi scrubbers are also effective in controlling emissions of hazardous substances and can be used in processes where gas streams contain high concentrations of pollutants.

Industries involved

frequently asked questions

Some answers to frequently asked questions about our industry

In the world of industrial air scrubber technologies there are three main configurations:

- Vertical “packed bed” scrubbers

- Jet scrubbers (with empty section)

- Horizontal scrubbers

- Venturi scrubbers

The term scrubber generally refers to technologies for the purification of industrial emissions, which use water (clean, or with chemical or biological reagents) to literally wash (scrub) the air.

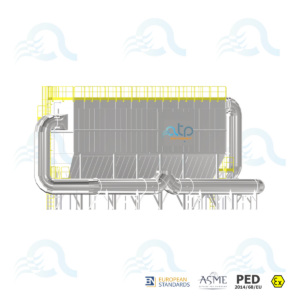

The dimensions of scrubbers for the treatment of industrial fumes depend mainly on the air flow rate to be treated. However, other factors also influence their dimensions, such as the required abatement efficiency and the composition of the gases. The type of scrubber chosen significantly affects the footprint:

- Vertical scrubbers take up less floor space, but require more space in height

- Horizontal scrubbers, on the other hand, require a greater horizontal area, but reduce the footprint in height and allow for greater weight distribution

Efficiency can be calculated as the percentage reduction of pollutants at the exit of the treatment on the initial input value. The treatment of industrial fumes with a scrubber technology can reach high levels of efficiency, depending on the composition of the incoming gases and the correct engineering of the air treatment plant. In some cases, scrubbers can reach 99% efficiency on the reduction. To have a high reduction efficiency in the most severe cases of contamination it is necessary to contact experts such as the team of engineers at ATP environment.

In the case of water-soluble VOCs, the recommended technologies for odor treatment are air scrubbers, bioscrubbers and biofilters. In general, removing unpleasant or nauseating odors from the air coming from industrial processes is not a trivial matter as the substances that generate them can be of various natures. For this reason is important to conduct a gas analysis and consult with an air treatment expert such as ATP environment that can identify the best technology for your odor problem.

The technology for the abatement of dust and other kinds of PM (particulate matter) from air currents must be chosen based on the size, weight and composition of the dust and the air flow that contains it. In fact, depending on the industrial process of origin, the air can contain different types of dust, such as:

- metallic dust

- plastic particles

- dust from the food industry (starch, shells, flours)

- dust from waste treatment

- dust from the recycling of batteries and electronic components

and many others. In many cases the best solution is wet technologies such as the venturi scrubber, or dry technologies such as bag filters or absolute filters. If you have a problem with PM emissions contact ATP environment team to know which technology best suits your application.

![ISO 9001 [Italy] ISO 9001 [Italy]](https://atpenvironment.com/wp-content/uploads/elementor/thumbs/ISO-9001-Italy-1-e1734709424454-qysjxm32zf8e8mhshe2a1tecm8cbvnzg0wb4e904dc.jpg)